First-class

tailor-made

services

Hot Tapping

EXCAVATION AND EQUIPMENT PREPARATION

To access the pipeline to be drilled, an excavation must be performed by the client in accordance with the construction and CNESST security standards.

To prevent contaminating the water line while hot tapping, all surfaces in contact with drinking water, being the pipe, the tapping sleeve, the tapping valve and the drilling equipment, are cleaned with a chlorinated solution.

QuotationEQUIPMENT INSTALLATION

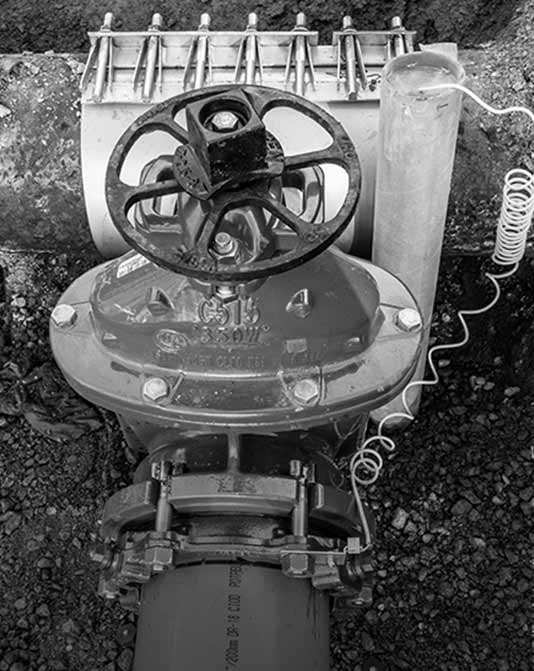

Once all the parts and surfaces to be in contact with drinking water are clean, we install them. The tapping sleeve and the tapping valve are installed using bolts, tightened according to the manufacturer’s standard sizing. The assembly tightness is then validated through hydrostatic testing.

QuotationPERFORATION

The drilling equipment is installed as soon as the tightness is validated. The pipe is drilled in accordance with the prescribed dimensions, prior to removing the cutter and closing the tapping valve.

QuotationConcrete Pressure Pipe Intervention

EXCAVATION AND ADJUSTMENT OF PARTS TO BE WELDED

To access an underground pipe that needs a repair, alteration or adjustment welding, an excavation is required for parts preparation.

We have every equipment and enclosed space certifications to perform interventions in valve chambers, for both complete reconstructions and hot tapping.

Before actually welding the required parts, we make the proper adjustments by means of clamps, pull-lift hoists or any other proper-part-positioning tools.

QuotationWELDING

Only Emploi-Québec pressure-vessel-welding-certified welders can perform welding interventions on concrete pressure pipes. The welding procedures meet the ASME standards at all times. Our repair, alteration and adjustment interventions can be performed on concrete pressure piping with diameters of up to 108”.

QuotationTESTING AND PIPE CONCRETING

Upon request and when possible, we conduct a magnetic particle inspection or ultra-sound to validate the welding conformity. If the test is approved, we use quick-setting cement, non-shrinking grout or Denso tape, depending on Forterra’s recommendations, to concrete the pipe.

QuotationTemporary

Line

Stopping

CONFIRMATION OF PIPE INFORMATION

Prior to undertaking the line stopping procedures, we must confirm the intervention feasibility. We must know the pipe water flow as well as type and grade to validate the inner and outer diameters.

Once we have all the required information, we can order the needed parts, after which the client can perform the excavation in accordance with the construction and CNESST security standards in effect.

QuotationINSTALLATION OF LINE STOP SLEEVE

Prior to installing the equipment, we prepare the surfaces in contact with drinking water by spraying a chlorinated solution. The line stop sleeve can then be attached. Like any pressure intervention, we conduct hydrostatic testing to validate the assembly tightness.

QuotationCONCRETE BED POURING

To ensure assembly stability and stopping equipment support, a concrete bed is required underneath the pipe and on the side, until it covers the line stop sleeve up to the top of the pipe. Once the installation is completed and the site is ready, we bring the required equipment on site to drill the pipe and stop the line.

QuotationEQUIPMENT INSTALLATION

We install the temporary knife valve on the line stop sleeve, as well as the tapping machine. A second hydrostatic testing is conducted once the installation of the equipment is completed.

QuotationLINE STOPPER INSTALLATION

The line stopper is installed, and the stop valve is deployed in the pipe. In order for the client to perform his intervention, we blow out the line to validate the stopping tightness by means of the de-pressuring saddle. If the test is approved, the client can proceed with the fluid draining and then the required intervention.

QuotationCOMPLETION OF INTERVENTION

To remove the deployed stop valve, the pressure on both sides must be equalized through re-pressuring. Once the line stopping equipment is removed, the plug is installed inside the sleeve and the temporary valve is removed. The blind flange can finally be installed, and the intervention is completed.

QuotationValve

Insertion

EXCAVATION AND EQUIPMENT PREPARATION

To access the water main and insert the EZ Valve, an excavation must be performed in accordance with the construction and CNESST security standards in effect.

We prepare, clean and spray the pipe and EZ insertion valve with a chlorinated solution. The gasket contact pipe sections need to be lubricated with NSF grease for easy rotation during milling.

QuotationVALVE AND MILLING MACHINING INSTALLATION

The ductile iron valve base, also called castings, is attached with stainless steel bolts. After closing the integral isolation valve, we conduct hydrostatic testing to validate the assembly tightness. The milling tool and rotational control assembly are then attached and the isolation valve is opened.

QuotationMILLING

While maintaining the pipe pressure, we mill a slot of a certain depth over a 120° or 140° path. This slot is used to slide in the EZ Valve knife and allow for the valve resilient wedge in the pipe invert.

QuotationVALVE OPERATION

Once we completed the slot milling and closed the isolation valve, the removed milling tool is replaced with the removable valve bonnet to block off water. The rotational control assembly is removed as well, and the bolts are tightened. We finally reopen the isolation valve to operate the EZ Valve as needed.

QuotationWe have highly qualified experts for projects of any complexity.

ExpertiseNothing but quality

At Houle H2O, pressure interventions are performed by a team of noteworthy qualified experts that show professionalism and great knowledge. Our technicians all have their P6C-certified CCQ card. Every product also meets the AWWA and NSF standards.